- Standard 2-Axis

- 3-Axis With Milling

- Multi Axis (Sub spindle/Dual Turret)

- Chucking (No Tailstock)

- Flat Bed

- Big Bore/Oil Country/Hollow Spindle

- Axis Definitions

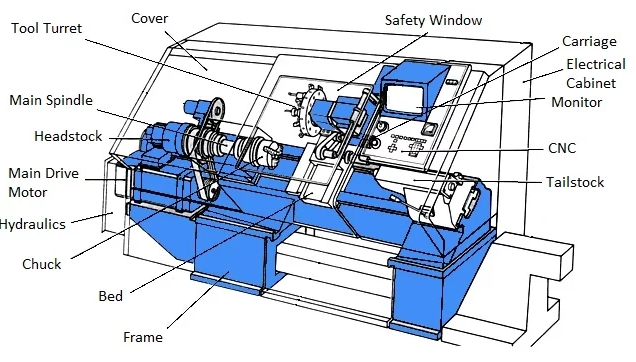

STANDARD 2-AXIS CNC LATHE/TURNING CENTER

A standard lathe is used for removing material from a part by using a variety of tooling and cutters depending on the specific result the operator is looking to achieve. Standard 2-axis CNC lathes use O.D. tooling to remove material from the outside of the part and Boring Bar holders to remove material from the center. Generally, CNC Lathes have a single spindle, a turret and a tailstock. The length, diameter, and weight of the part being turned can make the overall capacity of the lathe vary.

There are many brands that manufacture CNC Lathes. Among those are Okuma, Mazak, Haas, Daewoo, Doosan, Hardinge, Hwacheon, Johnford, Ikegai, Hyndai Wia, Leadwell, Milltronics, DMG , Mori Seiki and many others.

Things to consider when inspecting a CNC lathe:

Checking the electrical cabinet for any obvious repairs, changes or add-ons as well as its overall state of maintenance is crucial to a CNC lathe’s overall condition. Is it clean and neat? Is it dirty with loose wiring and missing/damaged components?

Listening to the machine running can tell you a lot about the condition of the lathe. The sound of the spindle can alert you to bearing issues, belt wear and other common wear-issues. Once you know how the machine sounds, it’s important to inspect the turret to see if the turret seats properly when it is indexed or does it retract out of balance? Are there any signs of a previous crash, as well as dings, marks or divots in the turret itself? You also want to check if the turret indexes smoothly and sound quiet.

It’s also necessary to know the way surface condition when inspecting CNC lathes. Make sure to check if the ways are getting good lubrication and are not dry, and see if there are any wear marks visible. The ways should be shiny, smooth and have a good amount of oil on them.

There are many different CNC control manufacturers on the market including: Fanuc, Mitsubishi, Haas, Okuma OSP and more. So considering the CNC Control is essential when inspecting a CNC lathe. It is important to pull the hours on the lathe. This will give you an indication of the number of shifts the lathe typically ran. Keep in mind however, that hours don’t tell the whole story – a machine that has a lower amount of hours might not be as well maintained, whereas a lathe that logged a lot of hours can still be in great condition through regular maintenance.

There are many different CNC control manufacturers on the market including: Fanuc, Mitsubishi, Haas, Okuma OSP and more. So considering the CNC Control is essential when inspecting a CNC lathe. It is important to pull the hours on the lathe. This will give you an indication of the number of shifts the lathe typically ran. Keep in mind however, that hours don’t tell the whole story – a machine that has a lower amount of hours might not be as well maintained, whereas a lathe that logged a lot of hours can still be in great condition through regular maintenance.

3-AXIS CNC LATHE

A 3-Axis CNC Lathe is similar to the 2-Axis, but adds the live tooling – or milling – feature. The 3-axis CNC lathe allows the operator to do standard lathe work with the option to mill and drill the part, as well as using a high-speed live tool, kind of like having two machines in one.

There are different types of live tool holders, ranging from radial (90° head) and axial (straight thru) styles. There are two configurations when mounting these holders to the turret – either on the outside edge of the turret or on the face of the turret. Live tool holders can also be offered in single spindle, dual spindle or multi-spindle configurations.

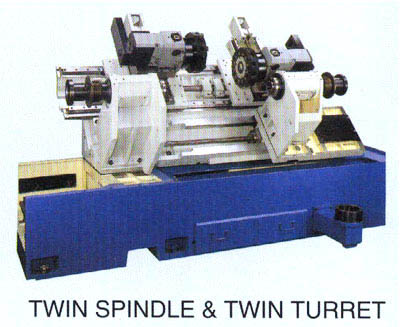

MULTI-SPINDLE/DUAL-TURRET

Another style of CNC Lathe, is a multi-spindle/dual turret lathe, which have two spindles and two turrets. A multi-spindle lathe can have either a dual spindle, meaning two spindles of equal size and power, or a sub-spindle, meaning that the spindle to the right is usually smaller in capacity and horsepower. Because of the two spindles and turrets, this allows the operator to turn both sides of the part in 1 operation, rather than turning one side, removing it and putting it back in the lathe to do turn the other side.

Another style of CNC Lathe, is a multi-spindle/dual turret lathe, which have two spindles and two turrets. A multi-spindle lathe can have either a dual spindle, meaning two spindles of equal size and power, or a sub-spindle, meaning that the spindle to the right is usually smaller in capacity and horsepower. Because of the two spindles and turrets, this allows the operator to turn both sides of the part in 1 operation, rather than turning one side, removing it and putting it back in the lathe to do turn the other side.

Most configurations allow for the part to be automatically passed off between the two opposed spindles. The operator can do both sides of the part without the need to set the part up a second time. There are two turrets an upper and lower – one being used for the left spindle and the other for the right. They can include live tooling on either one or both of these turrets. Many times this style of lathe also includes a bar feed interface to allow automatic loading of the bar stock for higher production jobs. Overall, this style of lathe allows multiple operations in a single setup, which helps reduce set up times and also increase accuracy.

CHUCKING LATHE

A Chucking CNC Lathe is a lathe that has no tailstock, it’s generally used for small second operation turning. Chucking lathes have a smaller capacity than a standard 2-Axis Lathe, and have a standard turret or gang-style tooling. Parts run on a chucker are usually short and small due to its lack of a tailstock for support of the part.

FLAT BED CNC LATHE

Flat Bed CNC Lathes offer a removable gap for larger turning diameters. Flat Beds however, do not have the typical 30° or 45° slant bed that a CNC Lathe is known for. Instead, they offer more open space for loading large, oversized parts. Brands such as Southwestern Industries make flatbed lathes that offer manual and CNC control in a machine. This helps for small production runs or simple one part projects. Flatbed CNC lathes are often less expensive than their slant bed counterparts.

BIG-BORE/OIL COUNTRY/HOLLOW SPINDLE

A Big Bore or Oil Field Lathe is a lathe with a large bore size that is typically 6” or larger. The oil field industry generally requires turning of large diameter parts such as rollers, flanges, shafts, pipes, etc. This style of lathe is also used in industries such as paper mills, ship building and repair, textile and energy applications. Due to the work these lathes generally do, they tend to have longer bed lengths (120”+) and many will also feature an outboard chuck mounted on the left side of the spindle.

AXIS DEFINITIONS

The movements of a CNC Lathe are defined by “Axis”. There are multiple variations for the term, below are some of the more common definitions for Axis Types:

X-Axis: The movement perpendicular to the spindle.

Z-Axis: The longitudinal movement of the turret.

Y-Axis: Vertical movement for milling/drilling operations.

C-Axis: This axis uses the spindle to position the part in the chuck at a specific degree.